High-Voltage Testing According to VW 80300 and LV 123

Including waveform libraries for:

LV123 | VW 80300 | VW 80303 | PSA | ISO 21498 | MBN LV 123 | ISO 7637-4 etc.

Empower Your EV Testing with Unmatched High Voltage Solutions

Modular, compact and flexible!

General

BOLAB's groundbreaking solutions for testing high voltage profiles in electric vehicles are exceptionally powerful, flexible, and modular.

Choose from three distinct options: high-speed testing for quick and accurate results, a versatile medium-range solution that covers a wide range of profiles, and a cost-effective option ideal for beginners and those looking to gain experience.

With BOLAB, you can access robust solutions that meet your specific needs, ensuring efficient and reliable testing of high voltage profiles in the electric vehicle industry.

Modular Design

BOLAB's systems are distinguished by their modularity, allowing you to start with a "small" 1 kW (1,000 V, 15 A) system and expand it module by module based on your application requirements and budget.

Never before has it been so simple to engage in high voltage testing for electric vehicles and gradually build up to a highly powerful solution. BOLAB empowers you to scale your testing capabilities at your own pace, ensuring a seamless and efficient testing process.

modularly extendable up to 54 kW (each module: 1.000 W, -30 V ... +70 V, 38 A)

Flexible

One of the most remarkable and unparalleled aspects of BOLAB's systems is their unparalleled flexibility.

Whether you are working with industry standards like LV 124, VW80000, LV 148, VDA 320, ISO 7637, or OEM-specific requirements, BOLAB's systems offer seamless compatibility. They are designed to handle the testing of DC/DC converters, accommodating both low- and high-voltage applications. This exceptional flexibility ensures that your testing needs are met across a wide range of standards and specifications, providing comprehensive and reliable results.

Powerful

BOLAB's systems have an extensive coverage of power requirements.

From 15 kW to 200 kW, these systems are capable of handling a wide range of power levels. With voltage capabilities up to 1,000 V and current ranges spanning from 15 A to over 400 A, BOLAB's systems offer a comprehensive solution for various applications. Whether you need to test high-power components or conduct demanding experiments, BOLAB's systems provide the necessary power capacity to meet your requirements effectively and efficiently.

Compact and Mobile

BOLAB systems offer a unique and unparalleled solution for high-end mobile testing of Electric Vehicles. Specifically, there is no other product on the market that provides a complete test solution for VW80000 with 15 kW (1,000 V / 15 A) in such a compact form factor—a small 19" rack with a height of only 10 U.

Moreover, BOLAB systems excel in their capability to cover a wide range of voltage profiles, including LV 124, LV 148, VW80000, VDA 320, and OEM standards. These systems can effectively handle voltage profiles up to 2000 A, providing comprehensive testing solutions that meet the industry's most stringent standards.

With BOLAB systems, you can confidently conduct your high-voltage testing for Electric Vehicles, knowing that you have access to a cutting-edge solution that offers exceptional performance and compliance with various industry standards.

High Voltage DC Power Supply +

4 Quadrant Amplifier In Series

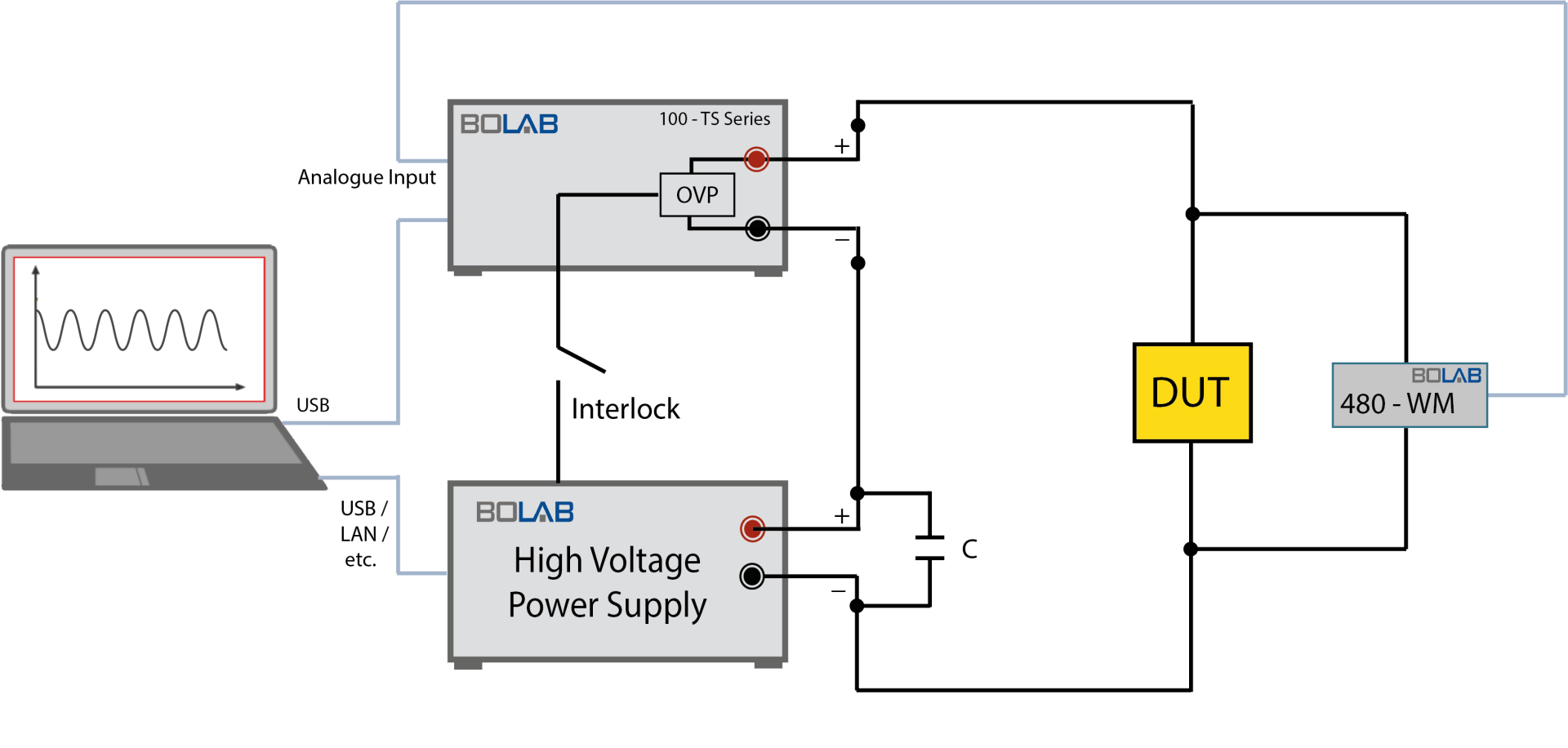

Setup

As coupling network transformers (CDN) have limitations in terms of speed, frequency ranges, and amplitude, they are not suitable for Load Dump applications, which are required in both LV 123 and VW 80300 standards.

Our most flexible solution is to combine a high voltage power supply in series with our 4-Quadrant Amplifiers. This setup allows for individual transients and Load Dump requirements to be met.

Furthermore, BOLAB's modular design enables easy adaptation to nearly all manufacturers of high voltage power supplies. This means there's no need to purchase an additional power supply if one is already available.

Advantages

- Highly Flexible: HV Test Systems from BOLAB are designed with a modular and scalable approach, offering flexibility in configuration to meet various testing requirements.

- Transient Interferences: Our HV Test Systems can generate precise transient interferences, allowing for accurate testing of components under real-world conditions.

- Load Dump Capabilities: With Load Dump capabilities, our test systems can simulate sudden voltage spikes, ensuring comprehensive testing of components' resilience.

- High Frequency Range: BOLAB's HV Test Systems cover a wide frequency range, making them suitable for testing high-speed and high-frequency components.

Artificial Network

AN-Series

The AN-Series, an artificial network offered by BOLAB, is designed to accurately replicate the impedance of the vehicle power-net for component testing of voltage class B (high voltage) components. With its analog system boasting a bandwidth of up to 150 kHz, the AN-Series plays a critical role in ensuring the proper testing of such components in hybrid and electric vehicles. By effectively absorbing and reproducing interferences generated by the device under test, including ripple, dynamics, spikes, and other higher frequency noise, the artificial network creates conditions akin to those found in the high voltage power-net of vehicles.

This enables more comprehensive testing of component robustness and their ability to withstand internally generated noise. The utilization of the AN-Series artificial network not only brings efficiency and life-cycle testing closer to real-world conditions but also ensures compliance with standards such as ISO 21498, LV 123, IEC 61851-23, VW80300, MBN 11123, as well as internal norms. With the AN-Series, BOLAB provides a reliable solution that bridges the gap between laboratory testing and the demanding requirements of the automotive industry.

| MODELS | LV 123 | VW 80300 | ISO 21498 | MBN 11123 | Current |

|---|---|---|---|---|---|

| AN-AB-60 | ✔ | ✔ | - | - | 60 A |

| AN-CD-60 | - | - | ✔ | ✔ | 60 A |

| AN-ABCD-60 | ✔ | ✔ | ✔ | ✔ | 60 A |

| MODELS | LV 123 | VW 80300 | ISO 21498 | MBN 11123 | Current |

|---|---|---|---|---|---|

| AN-AB-300 | ✔ | ✔ | - | - | 300 A |

| AN-CD-300 | - | - | ✔ | ✔ | 300 A |

| AN-ABCD-300 | ✔ | ✔ | ✔ | ✔ | 300 A |

BOLAB'S FULL TURNKEY SOLUTION